Large New Zealand dairy processing plant removes cooling bottleneck with Visentia’s Halo-GEN CDE

Disinfection and water chemistry control of chilled water circuits is critical to maximise plant throughput

Situation

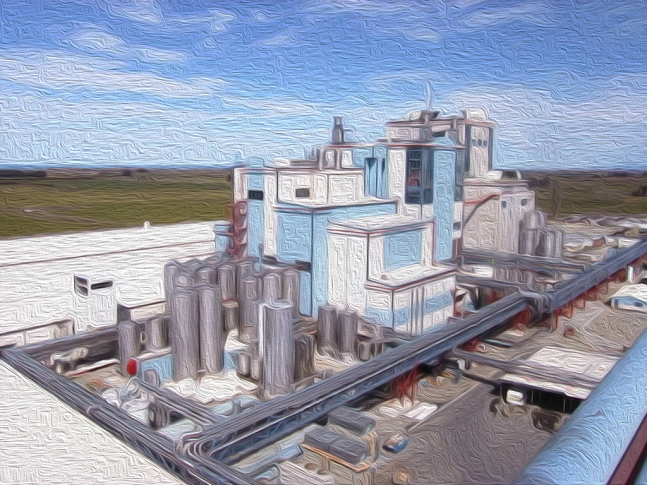

A large dairy processing operation in New Zealand was experiencing problems with their chilled water cooling system over the hot summer months. This plant produces a wide variety of dairy ingredients and consumer products and their chilled water systems are a critical part of maintaining throughput in many unit operations across the complex. The chilled water system is utilised for process cooling to crystalise protein out of suspension. The reduced cooling effectiveness meant that operators were limiting production throughput in order to maintain system temperatures, protein quality and separation efficiency.

Visentia was asked to come in and investigate the problems with this system. A thorough review of the process and water streams confirmed that this system had unresolved leaks in heat exchangers that were allowing the process stream to contaminate the chilled water. Turbidity monitoring of the chilled water showed that the contamination was intermittent.

The contamination in turn creates a large food source for microorganisms present in the chilled water, and if left untreated can lead to the formation of biofilms on the piping and heat exchanger surfaces, which reduces the cooling capacity and efficiency of the system. The leaks, while not ideal need to be managed by the water treatment program in order to mitigate the problems. Inspection of the heat exchangers confirmed significant fouling and so it seemed that the current programme was not controlling the microorganisms effectively.

Solution

The situation called for a water treatment programme that can maintain control of the microorganisms even when spikes of process contamination occur, which are intermittent and unpredictable. Visentia recommended their Halo-GEN electrochemical Chlorine Dioxide generation system to maintain disinfection of the system at all times. Chlorine Dioxide is the chemistry of choice for a couple of reasons:

1. Unlike conventional Chlorine, Chlorine Dioxide’s biocidal activity is not deactivated by proteins that can be present in the chilled water, therefore it keeps working even when there are heavy process leaks.

2. Chlorine dioxide is proven to be highly effective at removing biofilm since it penetrates deep into the layers and dislodges them, thereby returning contaminated systems to a clean state.

The electrochemical method of Chlorine Dioxide generation offers benefits over conventional generation methods such as reduced equipment and chemical footprint on site, increased reliability and control and increased safety due to not requiring to store and use dangerous acids on site. Visentia also recommended installation of a DPD Chlorine Dioxide analyser to measure the chemical reserve of Chlorine Dioxide continuously. This methodology is superior to other techniques like oxidation – reduction potential (ORP), which are non-specific. Using this measurement to control chemical dosing also prevents under/over dosing, which can lead to poor treatment and/or high chemical costs related to dosing too much chemical when it is not needed.

Results

Since installation of Visentia’s Halo-GEN Chlorine Dioxide system, the biofilm fouling has been removed and heat exchanger surfaces remain clean. This has resulted in removal of the plant bottleneck in the protein crystallisers allowing production to be maintained at design capacity at all times of the year. Also, refrigeration efficiencies have improved resulting in annualised energy savings of $250,000.

Implementation of a routine monitoring programme by a Visentia Water Treatment Consultant on the chilled water chemistry ensures that any problems with the water system can be detected early and remedial actions taken.

Further Information

For a pdf verson of this Case Study please click here.

If you require any further details on Visentia’s Halo-GEN Chlorine Dioxide generator system, please call your local Visentia water treatment consultant or directly to our Auckland head office on +64 9 216 9824.